Tips for Electronic Printed circuit Board Design

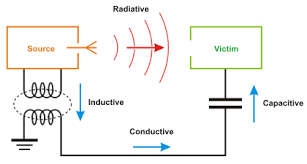

EMI/EMC problems may be approached at the component, PC board or

enclosure levels. However, it is much more

efficient to deal with these problems as close to the source or susceptible

victim as possible. Therefore, it is

important to consider these tips as guidelines for PCB design and layout so that

problems may be identified and prevented prior to actual fabrication of the

equipment.

(1) EMI controls should be applied at the circuit and box levels

prior to addressing EMI at the interconnected and system levels.

(2) Digital circuits are more likely to be the source of emissions

due to the handling of periodic waveforms and the fast clock/switching

rates. Analog circuits are more

likely to be the susceptible victims due to higher gain functions.

(3) The source or susceptible victim of most EMI problems is

typically an electronic component. Although active components are usually the sources of EMI, passive

components often contribute to it, depending on the signal frequencies and

component's characteristics. For example, an inductor can become

predominantly capacitive due to the high frequency parasitic coupling between

windings. A capacitor can develop

parasitic series inductance due to its internal inductance and external lead

inductance at high fundamental and harmonic frequencies.

(4) EMI problems involving an active component can be the result

of the device's output transferring the emissions or its input providing the

path for susceptibility. However, at high frequencies the active component may become a

direct radiator or receptor of EMI. Also, the component’s power and ground connections can provide

paths for both emissions and susceptibility.

(5) Although common mode currents are usually small compared to

differential mode currents, they can be the main cause of radiated emissions.

(6) Emissions and susceptibility that are typical in single layer,

free wired (using power and ground traces instead of planes) PC Board design,

can be greatly improved by using multi-layer PC boards with power planes. High capacitance between a forward signal and

its return path (ground plane) provides containment of the electric

field. Low inductance of the paths provides for magnetic flux

cancellation. Although not always

realistic in a PCB stack-up design, a trace should be spaced one dielectric layer

away from its associated return path and the voltage and ground planes should

be as closely spaced as possible.

(7) PCB stack-up design is important in containing the

electromagnetic fields, while providing for additional bypassing and decoupling

of the power bus and minimizing bus voltage transients. Some of the benefits of multi-layer PC board

design with power planes are:

a. The power planes, if properly designed, will provide an image

plane effect. Since the return

currents in the power planes are equal and opposite polarity to the associated

signal currents, their electromagnetic fields will tend to cancel. Power planes can also reduce the loop areas of

signal and power traces, resulting in a decrease of EMI emissions and

susceptibility.

b. A ground plane can lower the overall ground

impedance, thus reducing high frequency ground bounce. Also, the impedance between the ground and

voltage planes is lowered at the high frequencies and this reduces power bus

ringing.

(8) Clocked IC’s with rapid output transitions can be very

demanding on voltage and current distribution components such as the power

supply, power bus, and power planes. The inductance of the power bus can prevent the rapid energy

transfer needed to meet the quick output transitions and fast rise times. This can be improved with the placement of

decoupling capacitors at the IC’s power pins. The capacitors must be properly selected in

their frequency response to deliver the energy needed at the IC’s output

frequency spectrum. However, as the number

of decoupling paths increase, so do the number of voltage drops across them and

this can result in power bus transients along with the associated common mode

emissions. This problem can be

minimized with proper power plane design in the area of the IC’s. The power plane acts as an effective high

frequency capacitor, and consequently, as an additional energy source needed

for cleaner IC outputs.

Happy Reading

Ruby

Comments

Post a Comment