FLEX & RIGID-FLEX CIRCUITS

Flex

& Rigid-Flex circuits can be shaped to fit where no other design can. They

are a hybrid of ordinary printed circuit boards and round wire, exhibiting

benefits of each.

In

essence, flexible circuits give you unlimited freedom of packaging geometry

while retaining the precision density and repeatability of printed circuits.

As

a high reliability replacement for wire and wire harness assemblies, flex

circuits provide a significant cost savings with no reduction in performance.

There

are a variety of terminations for flex circuits and we can provide all of these

as standard manufacturing process. Adding connectors and other minor component

assembly is a common practice when producing flex and rigid flex circuits.

· TYPES OF FLEX CIRCUITS

Below

you will find information regarding the different types of flexible circuits

from a single or double sided design to multi-layer technologies, including

rigid flex circuit design specifications.

Single-Layer Flex Circuit

·

IPC 6013 - Type 1

·

One conductive layer,

either bonded between two insulating layers or uncovered on one side.

·

Stiffeners, pins,

connectors, components, are optional.

Double-Sided Flex Circuit

·

IPC 6013, - Type 2

·

Two conductive layers

with an insulating layer between; outer layers may have covers or exposed pads.

·

Plated through-holes

provide connection between layers.

·

Stiffeners, pins,

connectors, components are optional.

Multi-Layer Flex Circuit

·

IPC 6013 - Type 3

·

Three or more flexible

conductive layers with flexible insulating layers between each one; outer

layers may have covers or exposed pads.

·

Plated through-holes

provide connection between layers.

·

Controlled impedance possible.

Rigid-Flex Circuit

·

IPC 6013 - Type 4

·

Two or more conductive

layers with either flexible or rigid insulation material as insulators between

each one; outer layers may have covers or exposed pads.

·

Rigid-flex has

conductors on the rigid layers, which differentiates it from multi-layer

circuits with stiffeners. Plated through-holes extend through both rigid and

flexible layers (with the exception of blind and buried vias). Rigid-flex costs

more than a standard circuit with stiffeners.

FLEX & RIGID-FLEX CIRCUIT BENEFITS

Flex

and Rigid-Flex circuits gives the ability to design your circuitry to fit the

device, instead of building a device to fit the circuit board. They are

designed for the rigors of aerospace, medical and military applications, with

dependable reliability.

Flex

circuits offer multiple advantages for anyone considering to use this

technology in a future project or if you’re trying to decide on re-engineering

your current design. Below you will find some key benefits of using flex and

rigid-flex circuit technology.

Package Size & Weight Reduction

Combination of design freedom, space, weight and component savings can reduce packaging requirements significantly when using flex circuits as compared to other solutions.

- Flexible circuit boards fit where no other solutions can.

- Flexible circuit boards are thin and light weight which enables a substantial packaging size reduction.

- They have the ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible.

- Space requirements can be minimized by applying the freedom of 3D packaging geometry.

- Utilizing a flex circuit solution into your design can offer a substantial weight reduction benefit over using wires and wire harnesses.

- Flexible circuits can be used to replace wiring reduces the errors common in hand wired assemblies

Reliability & Durability

·

Increased reliability by

eliminating interface connections (solder joints, connectors, contact crimps

etc.).

·

The fewer number of

interconnects, the fewer the sources of potential failure.

·

Rigid-Flex technology

which integrates both a flex circuit and a rigid PCB further reduces the number

of interconnects.

·

Flex circuit’s ductility

and low mass will reduce the impact of vibration and shock and improve

performance.

·

The exceptional thermal

stability of polyimide allows the circuit to withstand applications with

extreme heat, as the materials excellent thermal stability provides a better

base for surface mounting than traditional boards. Because the compliant base

film places less stress on soldered joints, thermal mismatch is less likely to

occur.

·

Used extensively in high

reliability military and medical applications.

Cost Savings

·

Thin and flexible

polyimide film requires a much smaller area, reducing the overall finished

assembly packaging size and material requirement costs.

·

Reduced assembly costs

are also seen as fewer parts are needed for the final assembled product.

·

A simplified PCB

assembly processes can reduce assembly errors as the flex circuit can only be

installed one way.

·

Flex circuits also

eliminate wire routing errors; reducing test time, rework, and rejects.

High Temperature Applications

·

Flex circuits materials

(polyimide) dissipate heat at a better rate than other dielectric materials

while providing the added benefits of vastly improved flexibility.

·

Can be exposed to

extreme temperature applications (up to - 200C to 400C).

·

Expansion and

contraction are minimized when using polyimide material.

·

Good chemical resistance

to oils, acids, gases etc.

·

Flex circuits offer

excellent radiation and UV exposure resistance.

High Density Applications

·

Flex material properties

work very well in high speed "Controlled Impedance" designs, which

allow better control of impedances.

·

Flexible circuits allow

for narrow lines giving way to high density device population. Denser device

populations and lighter conductors can be designed into a product, freeing

space for additional product features.

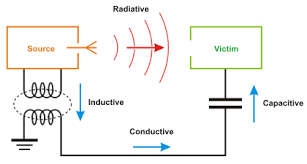

Shielded Applications

·

EMI and RF shielding is

available.

·

Multiple options

including sliver ink, copper layers, and EMI shielding films.

Component / Connector Assembly

·

Flex circuits can accept

any component or connector that can be assembled to a rigid PCB design.

·

Integrated ZIF contacts

provide simple modular interfaces to the system environment.

·

Additional options are

available such as, ZIF Connectors, crimped contacts, direct solder to PCB, etc.

Thanks,

If you are liking my article.. please share it..

Enjoy reading

Ruby

Comments

Post a Comment