Difference between through hole and Surface mount components

As technology grows the demand for less weight

and smaller size component increases. This leads to new improved technology

known as surface mount

technology (SMT). Surface mount components are similar to

plated through hole as far as there electrical function is concerned but the

key difference is in their size. The small size of surface mount components

(SMC) provides better electrical performance. Surface mount components are

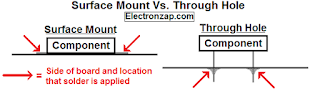

placed or mount directly on Printed circuit board (PCB) which means they do not

require hole for mounting the component. They can be directly soldered on track

side. Surface mount components have different shape leads and they have little

circular at bottom etc for soldering as shown in figure below.

SMD devices are mainly found in multi-layer

PCB where size of device is major concern. They can also be used on boards or

devices which contain both through hole and SMC because some components like

transformer, heat sink are not suitable for SMC.

It depends on the requirement of an individual

which technology is suitable between through hole or SMT. Like for beginners it

is easy to solder the through hole components than SMC's, but when it goes in

multilayer complicity increases and we have to chose SMT. There are some points

that makes SMT different from Through hole which are summarized below.

Difference between Trough hole and Surface

Mount Technology are as follows-

1. As SMC are small in size they take less

space in comparison to through hole. As you can see from figure the difference

between sizes of LED.

2. Pin count of component is increased greatly

in SMT as compared to old through hole for example the micro process used today

in computers PGA, FPGA etc.

3. SMC is leadless component and can be

directly mounted on board surface while through hole components required

drilling to mount the components. As shown in figure below.

4. The pads on the surface in SMT are not used

for connection of layers on the printed wiring boards.

5. Size of through hole component is large in

comparison to SMC there component density per unit area is more in

through hole component result in large size of Printed circuit board.

6. In SMT, components can be mounted on both

side of PCB, this is not possible in through hole. Therefore SMC has made

application possible which seems impossible with through hole.

7. SMT technology is used where large

production is required which leads to low cost of unit assemblies.

8. With the help of SMC higher performance

circuit can be made in small size which is prime requirement today.

9. Soldering of SMC is quite tough through

manual soldering. Hence machines are required therefore big capital investment

is required.

10. Designing, production, skills and

technology required in SMT is very advance as compared to through hole

technology.

11. Through hole technology is basically used

in prototyping.

12.

Soldering and de-soldering of through hole component is easy in comparison to

SMT. Hence replacement of component is easy.

Happy Reading..

Thanks,

Ruby

Very well described. It's really helpfull.

ReplyDeleteThanks Kanchan..

ReplyDelete