Interactive Placement and routing stratagies

PCB layout is a means to

combine your artistic side and your creative skills with the power of

automation. I always say that if a PCB design looks good, it will probably work

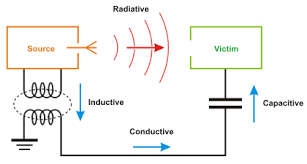

well. However, neatness in routing often leads to unwanted crosstalk as trace

segments are routed in parallel for long distances.

Interactive Placement - To obtain

a high route-completion rate, component placement is extremely important. If

the board is difficult to route, it may just be the result of poor placement,

slots/gates positioned all over the board, or perhaps the sequence of pins on

components are flipped. We need to help the router as much as possible by

opening route channels and providing space for vias.

Interactive placement is

best done by cross-probing and dragging the components one-by-one from the

schematic to place on the PCB—taking functionality and design constraints into

account.

During placement, consideration should not only be given to routing,

but also to inspection and rework. An 80 mil minimum clearance is required for

rework tools, and an angle of 60 degrees for visual inspection. However, where

possible, 45 degrees (i.e., spacing between components = height of tallest

component) is a good rule of thumb.

In other words, if a tall electrolytic

capacitor is next to a BGA, then the height of the electrolytic is the distance

required between components. Along these lines, grouping large, plated,

through-hole components together saves board space.

Similar types of components

should be aligned on the board in the same orientation for ease of component

placement, identification, inspection, and testing. A placement grid of 100

mils is recommended for large components and 25 mils for chip components. Also,

similar component types should be grouped together whenever possible, with the

net list or connectivity and circuit performance requirements ultimately

driving the placements. In memory boards, for example, all of the memory chips

are placed in a clearly defined matrix with pin 1 orientation in the same

direction for all components. This is a good design practice to carry out on

logic designs where there are many similar component types with different logic

functions in each package.

On the other hand, analog designs often require a

large variety of component types, making it understandably difficult to group

similar components together. Regardless of whether the design involves memory,

general logic, or analog components, it’s advisable to orient pin 1 on all IC

components the same, provided that product performance or function is not

compromised in the process.

One issue that is always a problem—especially as

trace widths and clearance decrease— is the lack of via space. With high-speed

design, traces from a BGA fan-out straight to an internal layer to prevent

radiation, and this of course requires a via for each BGA ball. This cannot be

avoided. But we can open up space for

vias on other surface mount devices (SMDs) when using double-sided placement.

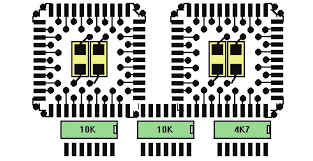

Figure Illustrates two PLCCs placed on the top of a board with resistor packs

on the bottom side. If the lands on the bottom are aligned with the lands on

the top, space is cleared for vias and horizontal routing channels are opened.

This is not the case when using blind vias, but certainly helps with

through-board vias.

A comment regarding autoplacement: One of the most useless

features that all EDA layout tools offer is autoplacement. I guess they all

have this feature because some bright guy decided to include this in his tools

and it then became a checkbox for product comparisons—so everyone has to have

it. Notwithstanding the uselessness for autoplacement’s intended purpose, I

have found a good use for it—to see if all the components will fit inside the

board outline before stating placement. If not, then you can re-evaluate the

packaging or reduce functionality to fit the required space.

Cross-probing- Cross-probing, between the schematic and PCB,

provides a valuable mechanism for design, review, verification and testing of

PCBs, but it is most powerful during interactive placement and routing.

Cross-probing is bi-directional, in that you can select parts or nets on the schematic

and highlight and identify them on the PCB database, or vice-versa. This

feature also gives you the ability to drive the router directly from the

schematic design.

Figure above illustrates a schematic to PCB cross-probe of a

component. Cross-probing can also be used as a powerful search tool—locating

parts and nets on the schematic or PCB. And, cross-probing is not limited to

schematic and PCB. AutoVue, for instance, allows the cross-probing between PCB

and 3D MCAD tools, enhancing mechanical visualization of the product.

When an

engineer creates the schematic he invokes a logical process, typically,

grouping components into blocks or sheets that functionally go together. When

the PCB designer then places these components, he should also use a logical, sequential

process by placing functional components near each other, optimizing trace

cross-overs and lengths, keeping constraints in mind.

In years past, I recall

having to place components by select list. This seemed logical but the PCB

designer was never to know whether they were placing a trivial static pull-up

resistor or a critical terminator. Resistors are just resistors—unless you know

what they do. This is the beauty of cross-probing. The functionality of the

circuit is displayed and each and every component can be placed by

functionality and importance—providing error-free transfer of the intended

schematic functionality to the design.

Of course, design rules can also be

added to the schematic to pass this information on to the PCB designer, but a picture

is worth a thousand words.

Interactive Routing- Proper component placement is an

important aspect of routing. If the board is difficult to route, it may just be

the result of poor placement. So before you start routing, it is important to

check the placement and design rules to ensure that there are no issues that

may prevent the route completion. The easiest way to check this is to turn the

autorouter loose and see how it goes. If you do not get at least 85% completion

on this first test route, then you may need to tweak the placement, look at

more appropriate packaging, adjust the design rules, and possibly drop some

functionality to improve routability.

However, there are some important things to do before you

commence with the process of formally routing the board:

1. The stackup should be planned to ensure that controlled

impedance signals have been calculated correctly and that the return current

for each signal layer has a clear return path. The ICD Stackup Planner can be

used to analyze the stackup (download from www. icd.com.au), and help you with

material selection, along with input from your fabricator. The resulting

stackup configuration should then be transferred to the design rules to define

the correct trace width and clearance for each layer, and to specify the

differential pairs.

2. The power distribution network (PDN) should be planned,

and bypass and decoupling capacitors placed in the appropriate positions. The

ICD PDN Planner is an ideal sandbox for analyzing this. It is a good idea to

color the power nets with individual colors so that they can easily be

recognized without having to name the net. Altium has a great feature, which

displays the net name for each net, making identification of power nets

extremely clear.

3. Design rules and

constraints can be passed from the schematic, which automatically sets the

design rules in the PCB database— though there is always some adjustment to be

done on the PCB side. Via sizes for different net classes need to be defined.

This is important for route completion. (Please see my previous article on PCB

Design Techniques for DDR, DDR2 & DDR3, Part 1 and Part 2 for a complete

list of the appropriate design rules for DDR2 routing.) For rules to properly support the design

process, they need to be defined in the correct priority so that the most

important rules prevail over rules of lesser importance.

4. Set up the routing

options. It amazes me that all the EDA tools that I have used do not come with

the router set to the most useful functions straight out of the box. So before routing,

one must tweak the route options to get the tool to do what you want. Details

vary by tool, of course, but the nuisance is near- universal.

Once we have the above set, then it is time to start

interactive routing. The real power of cross-probing is driving the router from

the schematic. Starting with the most critical nets, cross-probe in the

following sequence:

1. Select the components on the schematic and fan-out on the

PCB selecting the appropriate pattern. Adjust the fan-out as necessary. The

rules should be set such that power traces are routed thick (10 - 20 mils) to

reduce inductance. And, each GND and VCC should have its own individual via to

the plane—avoid connecting two or more GNDs to the one via.

2. Obviously, matched length, differential pair and critical

signals that have specific requirements should be routed first. Fix or lock

these traces so they cannot be inadvertently moved.

3. Select the most

critical nets, a few at a time, on the schematic and route in the PCB. Adjust

the routing as necessary then move on to the next group of nets and so on. In

this way you can build up an excellent route in a short time and it is all

controlled from the schematic. Feel free to jump in and tweak the routing to

your liking.

Once the routing is complete, apart from running design rule

checks (DRCs), I like to run a sanity check on the board. I can either do this

in the simulation environment or in the PCB database. Simply highlight each net

one by one—it is tedious, but gets results. You can quickly see if there are

any nets that are longer than the Manhattan length or spiral around the board

three times before termination.

Hope it will helpful for Readers...

Happy Reading...

Comments

Post a Comment